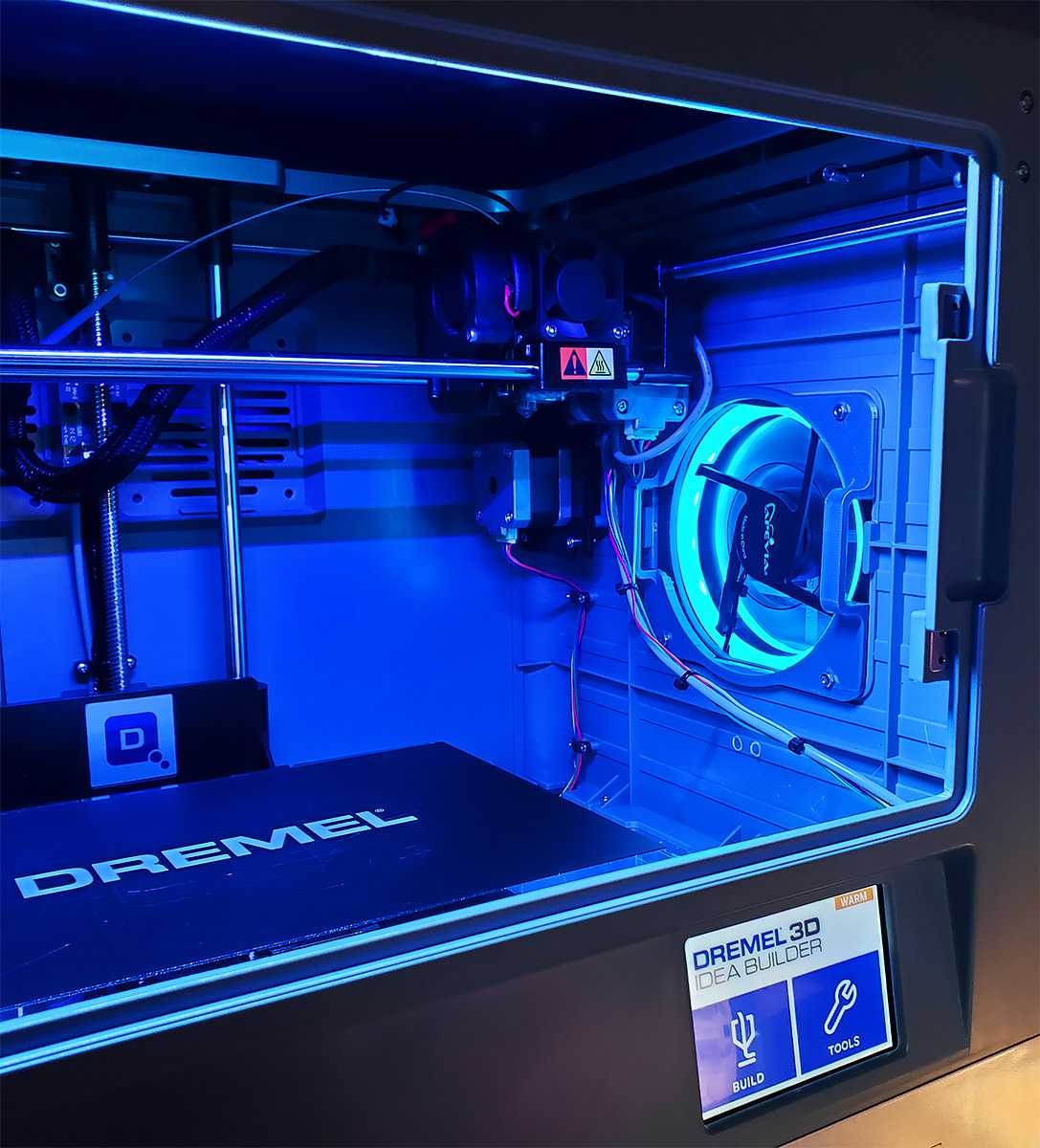

My initial reaction to the Dremel 3D20 printer years ago was love at first sight. I now own 5 of them and plan to buy one more before I tame the madness.

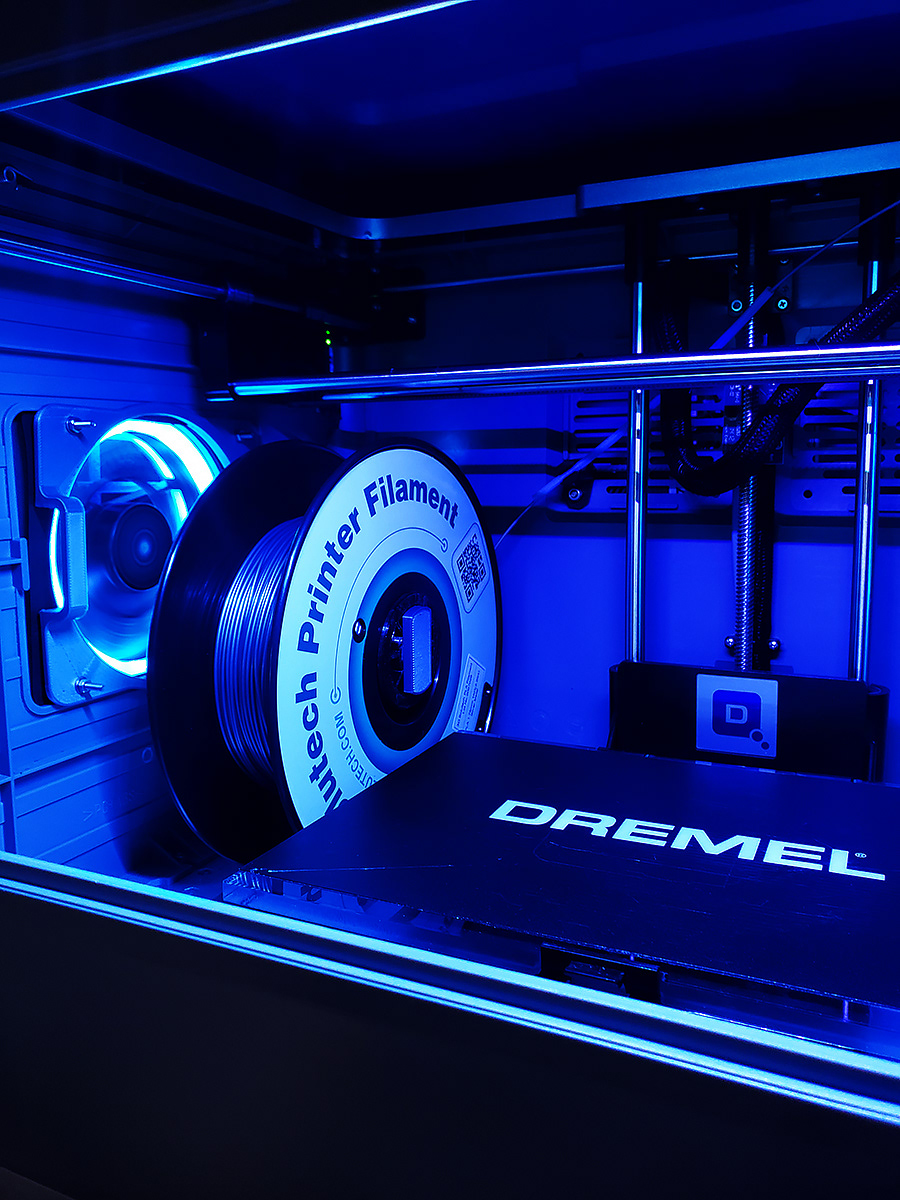

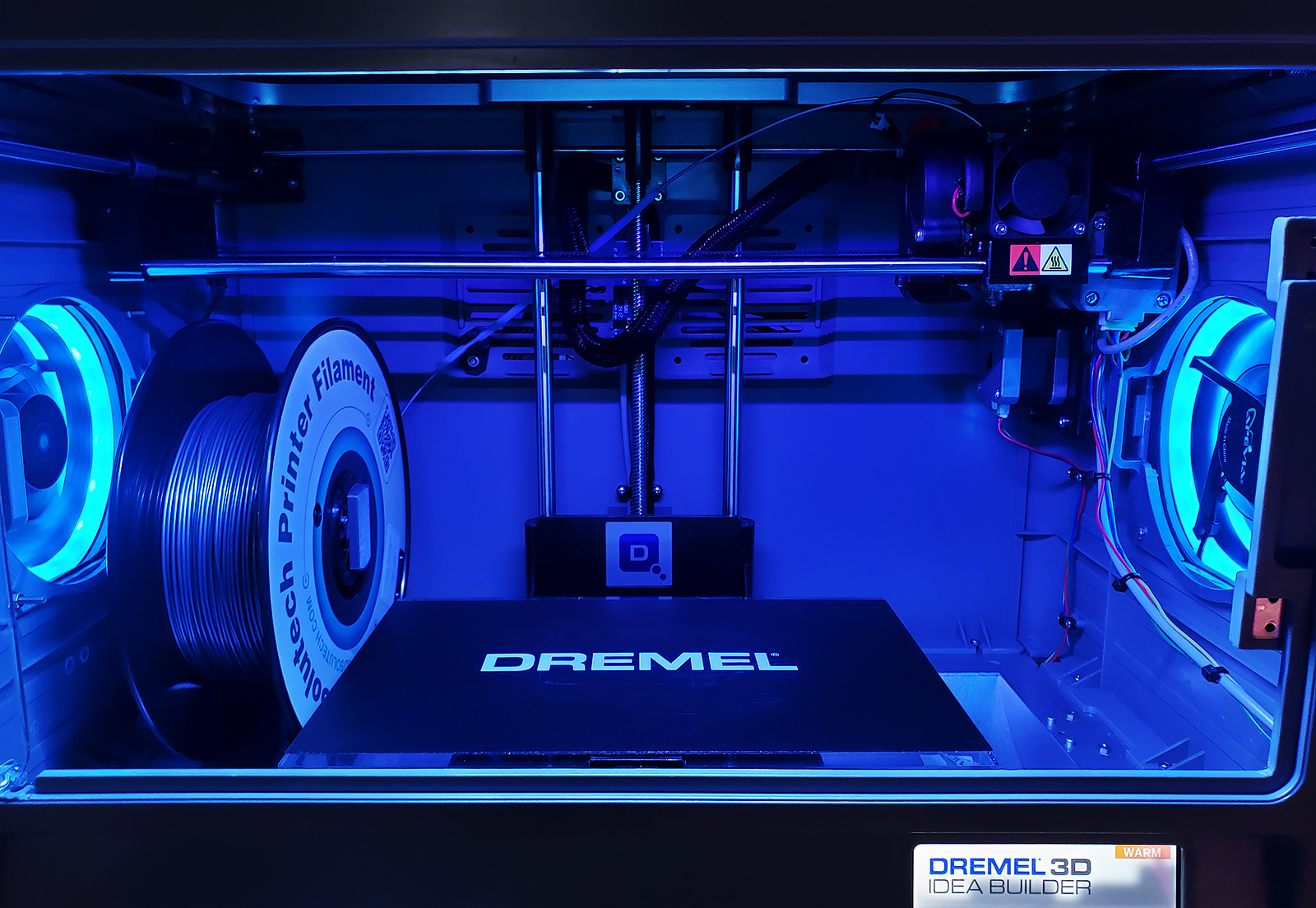

Let's face it - and for you that don't know much about this particular machine - the 3D20 is extremely mod and upgrade friendly. The enclosure is prepared with internal camera mounts (if you're into that), dual spool holder capability, two 80 mm fan ports, as well as two modular ventilation ports that nicely fits 120mm fans. The FlashForge controller board powering everything within is already outfitted and for dual head printing, a heated bed and more.

However this particular printer does not have a heated bed and out-of-the-box best suited for PLA.

The idea seemed however clear - What if I just insulate the printers well, and use a 12V power supply to drive ventilation fans (2 per machine) that circulate sealed and conditioned air within the 3D print farm machine enclosures. Perhaps it will not be too difficult to heat the beds by heating the chamber itself, using a small in-line heater and a digital temperature controller.

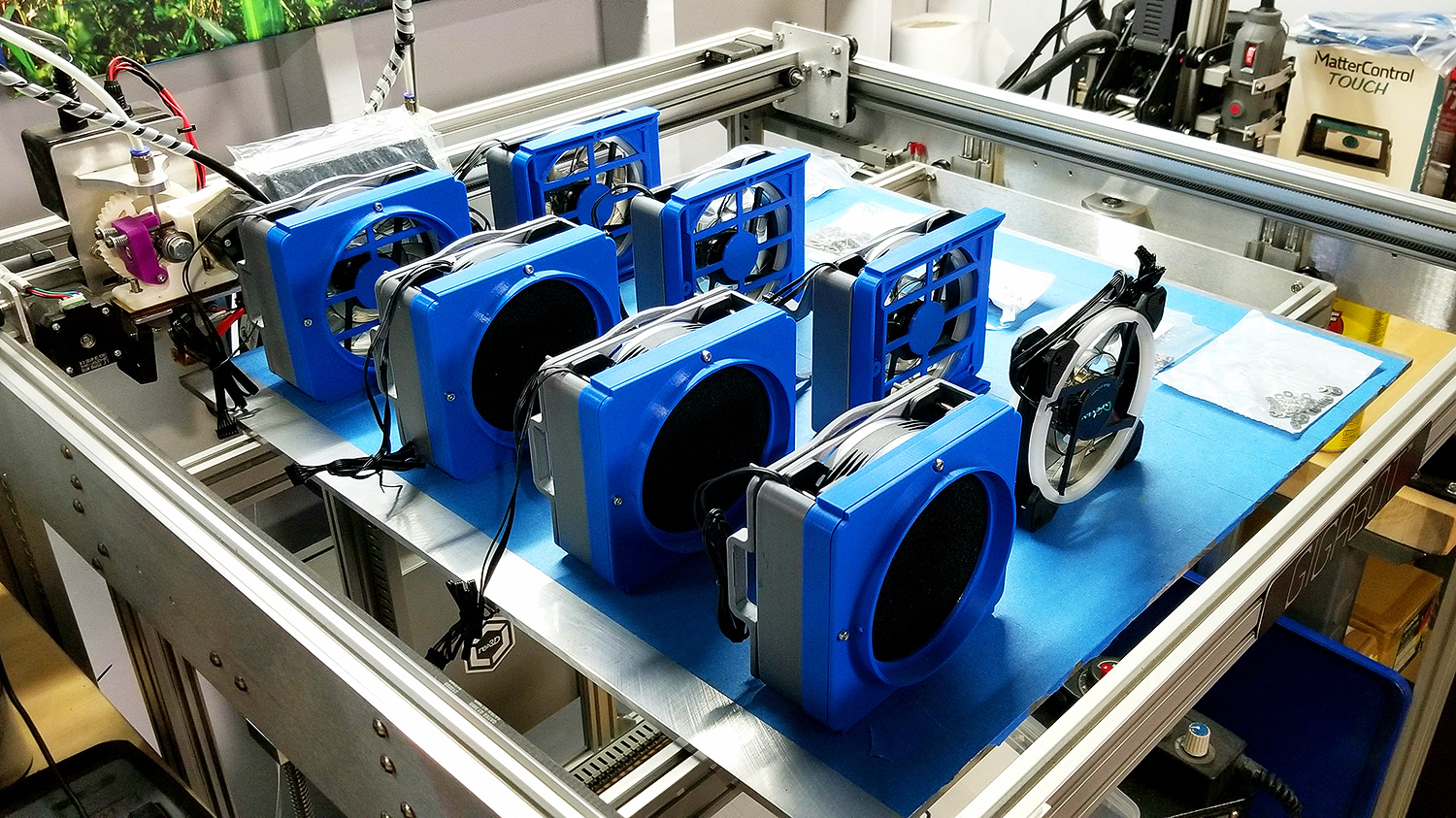

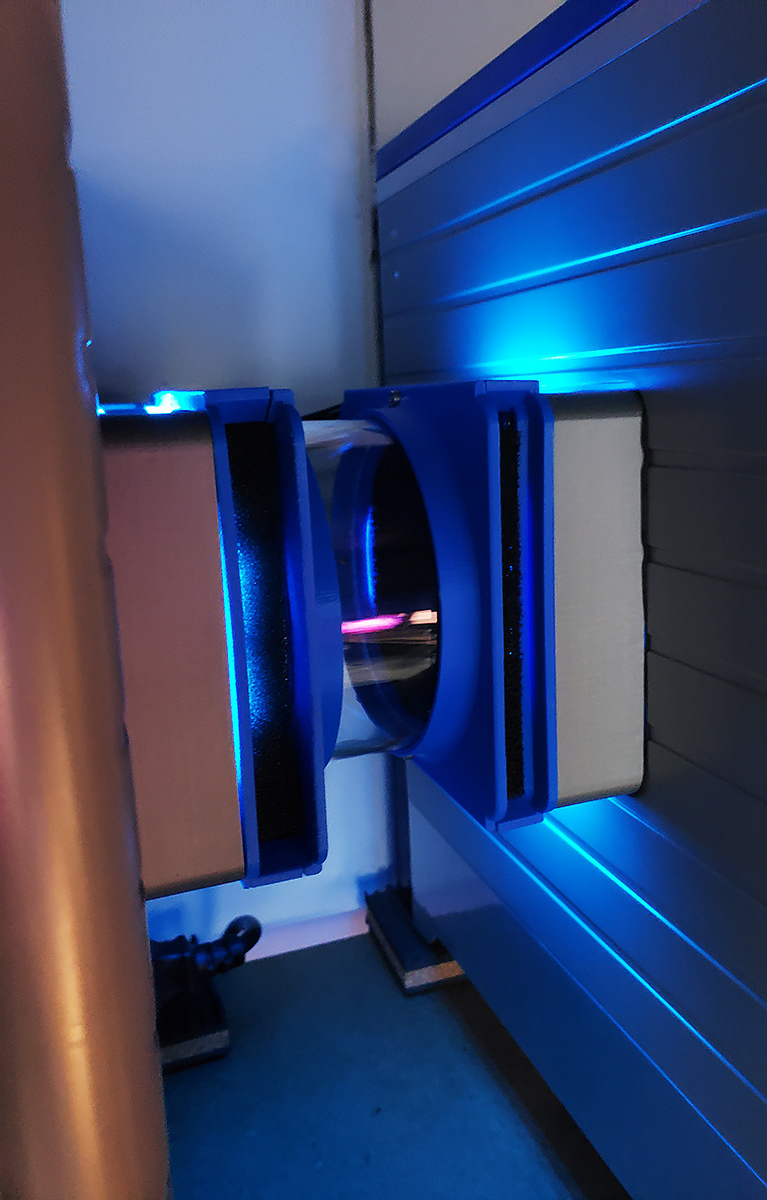

Air is circulating from one enclosure to the next, powered by two 120mm RGB computer fans per machine. A 100 mm acrylic tube directs air from one machine into the next.

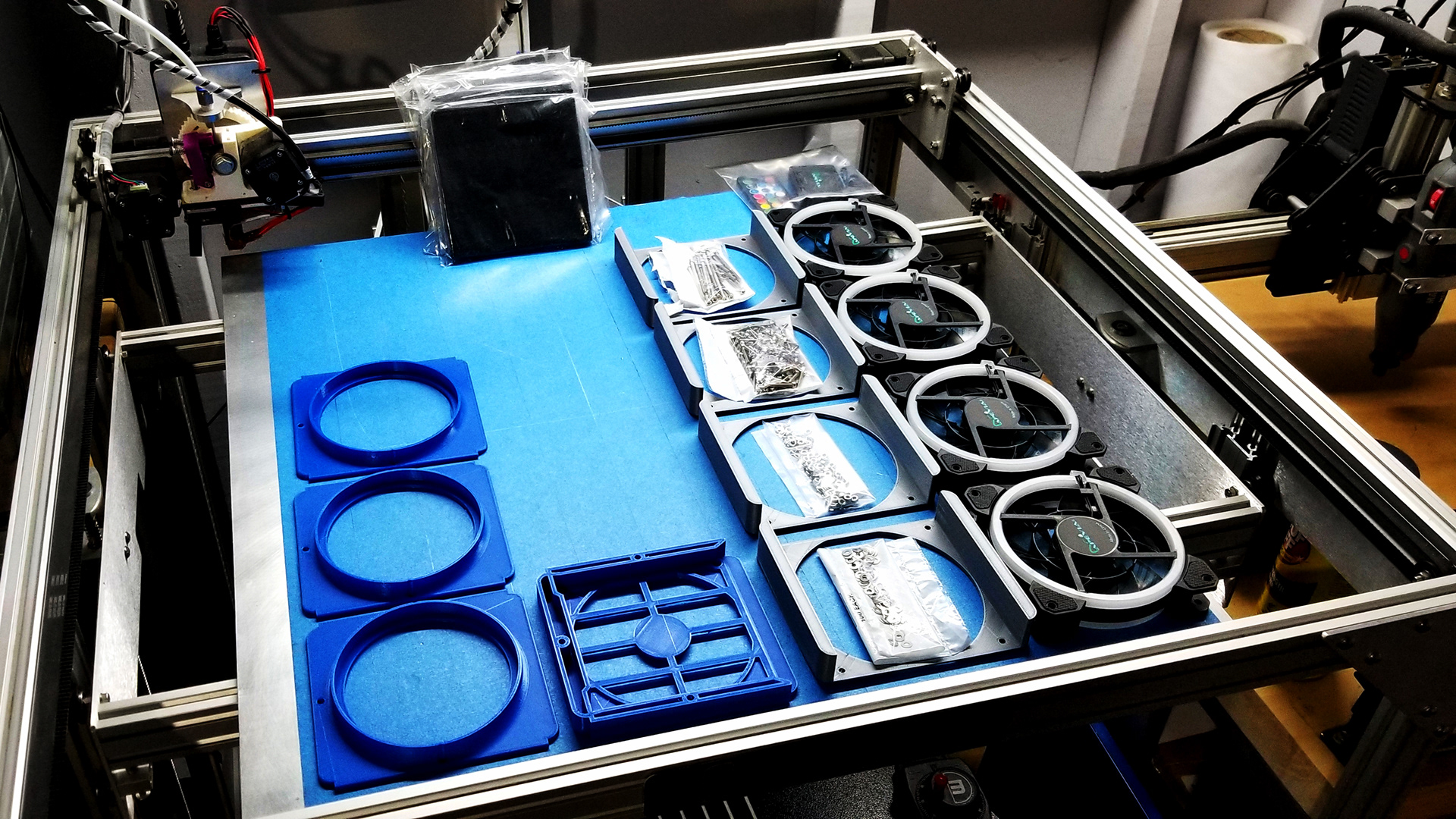

Each fan assembly also includes two replaceable air filters. One for fine particles used to prevent dust and debris from entering the printer enclosure on one side. And a charcoal activated filter for eliminating odor as the air exits the enclosure on the other side.

Exploded view of the air tunnel assembly from one printer enclosure to the next.

More pictures to final assembled 3D print farm AC system coming soon!